石油

在炼油装置中,加氢技术是最重要的炼化技术之一,其是确保油品质量升级和环保的关键技术措施。近年来我国加氢技术的推广应用发展很快,新建和升级改造了很多工业装置。

但是炼化企业的加氢装置又具有很典型的腐蚀环境,普遍存在硫化氢、硫化氢氨等等腐蚀环境。

阀门是在炼化装置中使用周期较长的管道器材,其在管道器材投资中占比较高,同时很多装置在苛刻条件下使用的阀门中有很多进口产品,投资高,制造周期长。

保证阀门的长期可靠是装置长期稳定安全运行的重要保障。加氢装置典型的腐蚀环境包括高温氢腐蚀、高温硫化氢腐蚀、高温硫腐蚀、高温氢损伤、氢脆、氯化铵腐蚀、硫氢化氨腐蚀、湿硫化氢腐蚀等。

因此选择具有较强的抗腐蚀能力的阀体材料显得格外重要,其是保证阀门寿命和安全的最关键因素。特别是在一些高硫、高酸原油环境下,各种的腐蚀问题犹为突出。

SSZ陶瓷阀门选用的是结陶瓷材料,完全颠覆了传统意义上的金属阀门,陶瓷材料,化学稳定性非常高,在耐腐蚀的测试中,对各种强腐蚀性的酸碱溶液的腐蚀性测试结果显示可以忽略或没有腐蚀(氢氟酸除外),这种得天独厚的优势,是任何的金属材料都无法比拟的。

选用的氧化锆陶瓷材料是高纯超细的氧化锆粉料,纯度达到99.95%,是陶瓷界机械强度最高的一种陶瓷材料硬度仅次于金刚石。

利用陶瓷材料的先天优势,达到耐腐蚀,耐磨损,抗冲刷的目的。

陶瓷球阀结构中,所有与介质接触的部分全部为陶瓷材料,同时陶瓷材料与金属件的结合采用的是最先进的热配工艺,结合之后的机械强度将达到3000Mpa,成为真正的陶瓷钢,给阀门的耐冲刷,耐冲击提供了最完美的保障。

化工

煤化工是指以煤为原料,经化学加工使煤转化为气体、液体和固体燃料以及化学品的过程。

主要包括煤的气化、液化、干馏,以及焦油加工和电石乙炔化工等。其工艺固有的介质高温、高流速、高压差、高腐蚀性、流体高含固量等工艺特点,对阀门的工况适应性以及整体寿命等提出了严峻的挑战。

尤其煤化工行业里气化炉黑水、灰水等严苛工况的介质中含有较高硬度及含量的固态颗粒、腐蚀性组分,对调节阀耐腐蚀、抗冲刷性能及整体寿命要求越来越高,所以这类严苛工况的阀门提高耐腐蚀抗冲刷性能,延长平均无故障周期和整体寿命成为了煤化工工业调节阀急需突破的难题。

黑水处理是将来自激冷罐、湿洗塔和除渣系统的废水和系统的雨水污水等回收处理再循环利用的水处理系统。

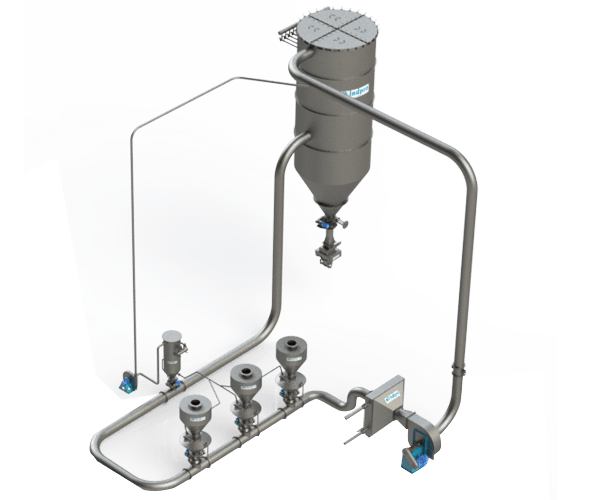

主要包括合成气洗涤系统、锁斗系统,合成气初步净化单元和黑水处理系统4个部分。

整个工艺就是来自气化炉激冷室、旋风分离器及水洗塔底部的高温黑水送往蒸发热水塔闪蒸并与洗涤灰水换热,同时使部分酸性气体解析,底部浓缩黑水经过低压、真空闪蒸进一步得到浓缩,经过澄清槽及灰水池分离出细渣和澄清灰水循环使用,部分灰水作为废水排放。

陶瓷球阀的结构与普通金属球阀相同,但阀球和阀座的材料被结构陶瓷材料所代替。

由于陶瓷材料具有良好的优越性,陶瓷阀门在腐蚀磨损方面可以替代普通的金属阀门。阀球与阀座之间密封保证了陶瓷阀门的密封性能。

在高腐蚀和强腐蚀的介质中,阀内件承受的腐蚀和冲击最大,将陶瓷材料作为阀内件,就可以很好地避免阀内件的腐蚀与磨损,并且,使得介质不会与阀体直接接触,有效的延长了阀门的使用寿命。

电力

火力发电厂湿法烟气脱硫环保技术因具有脱硫率高、煤质适用面宽、工艺技术成熟、稳定运转周期长、负荷变动影响小和烟气处理能力大等优点,广泛的应用于各大中型火力发电厂。

成为国内外火力发电厂烟气脱硫的主导工艺技术,但该工艺存在着介质腐蚀性强、处理烟气温度高、SO2吸收液固体含量大、磨损性强等缺点。

在火力发电厂中, 湿法烟气脱硫装置需用大量的阀门,只要了解湿法烟气脱硫工艺的特点, 根据装置各系统的特点合理选择阀门的类型, 解决阀门结构设计问题, 选择适宜的材料,就能提高其耐磨损和耐腐蚀性能。

控制火电厂和燃煤设备二氧化硫的排量, 防止环境污染,达到环保要求, 保证装置长期安全运行, 促进我国能源工业的可持续发展。

SSZ陶瓷阀已有30多年的陶瓷阀门经验,公司产品主要针对腐蚀、磨损工况,在电力系统主要应用为煤粉、石灰石浆液等磨损、腐蚀位置,公司产品线超过10余种。

陶瓷阀门通常寿命比金属阀长几倍甚至还多,为客户节约成本,提高生产效益。降低阀门的维修更换次数,提高配套设备运行系统的安全性、稳定性,节约设备修理费用,能最大限度的减小泄露,保护环境。

钢铁

在转炉吹炼过程中,转炉中产生约1450℃的高温废气,主要成分是一氧化碳、氧气、二氧化碳、氮气和二氧化硫,其中一氧化碳含量可高达80%以上。

含有大量的工业粉尘,含尘浓度可达105-300g/Nm3,吨钢可产生10-30kg工业粉尘。所以炼钢转炉烟气具有高温,有毒,易燃易爆、含尘量高等特点。

同时炼钢转炉烟气又具有很高的利用价值,具有潜热、显热等大量能量,烟气中的粉尘也含有50%以上的全铁,可以循环利用。

炼钢除尘中的烟气既有有腐蚀性,又有工业粉尘及铁粉的磨损,性能复杂,使得该部分的设备及通用零部件的要求相当的高。

陶瓷阀主要用在炼钢除尘与烧结之间的管道上,因为炼钢除尘中含铁很高,就把含铁尘灰注水成浆输送到烧结,与烧结料混合做成球团炼铁。

在输送过程中为控制好添加比例要进行浆液流量调节,这个环节被很多的使用者称为磨刀的场合,一般的金属阀门在这个场合只能用到两三个月,陶瓷球阀可以达到金属阀门使用寿命的6-8倍。

SSZ多年来一直非常重视工艺上的改善,在陶瓷件的生产过程中掌握了最优良的工艺过程控制技术。

利用先进的生产工艺,球芯的圆度精度可达到3μm以内,采用先进的研磨设备与阀座对研后,利用氧化锆陶瓷的自润滑性,可达到很好的密封效果。

加上产品结构上的独特的优点,陶瓷球阀可以达到硬密封ANSI VI ,可根据客户的需要做到零渗漏,并且由于氧化锆陶瓷天然的自润滑性,阀门的扭矩非常小,仅为硬密封金属球阀的十分之一。

造纸

在造纸泥浆管道中,阀门和管道易受腐蚀或磨损,易被粘性介质堵塞。

因此,陶瓷管道或阀门不仅可以解决磨损和腐蚀问题,而且可以解决堵塞或堵塞问题。它可以保证更好的生产,降低维护成本。

SSZ在产品工艺上,多年来一直非常重视工艺上的改善,在陶瓷件的生产过程中掌握了最优良的工艺过程控制参数。

利用先进的生产工艺,球芯的圆度精度可达到3um以内,球芯表面质量非常好,采用先进的研磨设备与阀座对研后,利用氧化锆陶瓷的自润滑性,可达到很好的密封效果。

加上产品结构上的独特的优点,陶瓷球阀可以达到硬密封ANSI VI 。并可根据客户的需要做到零泄漏。

并且由于结构陶瓷天然的自润滑性,使得阀门的扭矩非常小,仅为硬密封金属球阀的十分之一。

采矿

现场采用DN100金属闸阀,输送介质为氧化铝、氧化锌等颗粒物。

阀门密封件材料采用合金材质(通常密封件采用Stellite合金堆焊),长时间使用后会出现密封面受损;

此外,由于闸阀结构特性,介质在输送过程在阀腔中堆积中导致阀门无法开关到位,影响阀门正常使用。

应用特点

现场使用金属闸阀,经我司技术部门商讨后,推荐SSZ系列产品,预计阀门使用寿命可提高2~4倍。该产品优点如下:

1、盘阀密封方式为固定反作用力预紧,更适用于压力较低难以实现自紧密封的工况。

2、盘阀密封性受阀座与阀盘贴合度影响,使用时间越长,阀盘与阀座贴合度越高,密封性越好。

3、盘阀安装方式为垂直安装,进出料方式为上进下出,不会造成物料在阀体内堆积,特别适用于固体颗粒的气力输送工段。

硅业

金属硅通过破碎成硅粉后,和催化剂、氯甲烷一起加入到硫化床,进过洗涤塔滤出渣浆后经过粗单体塔获得粗单体。

硅粉和氯甲烷为有机硅生产的原料,硅块经过给料机送至破碎机进行初步破碎,再送至旋风磨,磨成硅粉,筛分后的合格硅粉由气力输送泵或槽车送至单体合成。

单体有机硅合成工段:由于材料原因,喷涂碳化钨及普通金属材料设备,在带有严重磨损及冲刷的硅粉合成工段,使用效果会低于陶瓷设备。

SSZ陶瓷产品具有耐高温、耐磨损、耐冲刷等性能可大大减少现场人力物力成本,减少现场阀门维修等耗材费用。

1、在结构陶瓷旋转阀中增加了阀座密封压缩,是在气动输送压力下生产二氧化硅的一大优势。

2、减少了阀门内的死区,确保侵蚀性细颗粒不会沉积在任何空腔中,从而避免硅粉结晶,导致陶瓷部件开裂。

3、用于所有陶瓷固定的增韧陶瓷比钢固定的增韧陶瓷。对于硅加工行业,在这一阶段,磨损比腐蚀更重要。

4、高级陶瓷旋转阀法兰出口处的平面陶瓷密封件是标准的,因此,确保所使用的密封件能够防止陶瓷堵塞时立即泄漏到大气中。HCL气体可以与大气中的水分反应形成盐酸。