公司简介

艾思瑞流体控制有限公司位于成都,其业务覆盖全球多个国家和地区。SSZ产品已遍布世界各地,并设有多个办事处。

公司拥有多项陶瓷核心技术。我们致力于解决耐磨、耐腐蚀的苛刻条件。自上海自贸区进入中国以来,服务中心的建立大大提高了服务和供应水平。

SSZ公司生产的要求条件(耐磨、耐腐蚀)的陶瓷阀门和陶瓷管件不断被添加到纳米陶瓷的研发中。我们一直在探索将陶瓷材料的性能提升到更高的水平来解决化工、石油、电力、矿业、多晶硅、二氧化钛、锂电等行业。

公司一直在寻求和努力,不断改进和创新,不断寻求最佳的解决磨损和腐蚀条件。 公司拥有丰富的陶瓷产品开发经验。无论哪里有腐蚀和研磨,我们的工程师都有一个特殊的解决方案。

SSZ工程师积累了丰富的应用经验。高纯度纳米陶瓷材料和计量技术是我们质量保证的基石。为了满足您更复杂的工作条件,我们将继续提高产品质量,取得更大的进步。

结构陶瓷

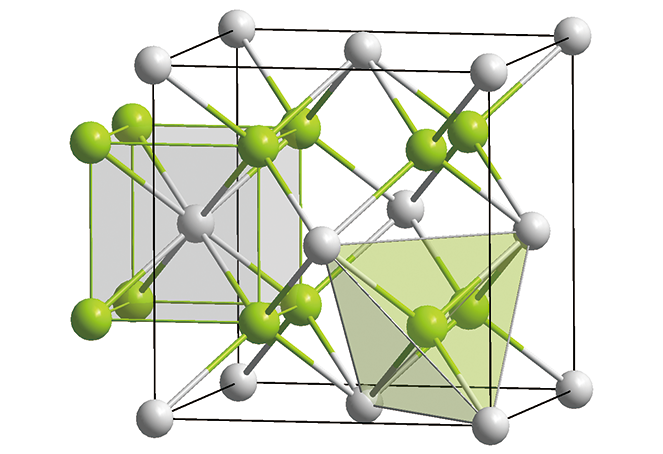

结构陶瓷是由天然或人工合成的粉状化合物,如单由Al2O3、ZrO2、SiC、Si3N4粉末,或者相互复合,或与碳纤维结合,经成型和高温烧结而制成的多晶固体。

普通陶瓷应用于器具制品,而结构陶瓷多应用于工业,航天。二者在成分、工艺、化学性能和物理性能上均有非常大的差异性。

结构陶瓷具有极好的化学稳定性,几乎不与任何化学介质反应,从而使全衬陶瓷密封球阀适用于绝大部分高腐蚀介质,除了具有极好的耐腐蚀性能外,结构陶瓷同样具有极高的硬度,它的硬度仅次于金刚石。

决定陶瓷性能的要素

陶瓷材料通常由三种不同的物相组成,即晶相、玻璃相和气相(气孔)。

晶相是陶瓷材料的主要组成相,是化合物或固溶体。晶相分为主晶相、次晶相和第三晶相等,主晶相对陶瓷材料的性能起决定性作用。

玻璃相是一种低熔点的非晶态固相。它的作用是粘接晶相,填充晶相间的空隙,提高致密度,降低烧结温度,抑制经晶粒长大等。

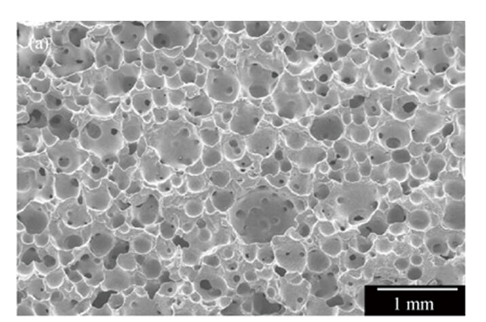

气相(气孔)是指陶瓷孔隙中的气体。陶瓷的性能受气孔的含量、形状、分布等的影响,从而对功能陶瓷的光、电、磁等性能也会产生一定的影响。

对陶瓷脆性处理办法

对陶瓷阀门而言,陶瓷先天性的弱点,如易碎和不耐高温差的冲击等,都是需要处理的。为了做出更加完美的陶瓷产品,几十年来,我们一直在解决这些问题,通过工程研究计算,我们总结的办法如下:

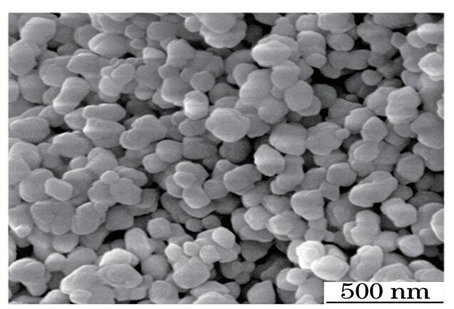

· 纳米陶瓷是解决陶瓷脆性的最好途径,同时保证所有的粉体颗粒均匀;

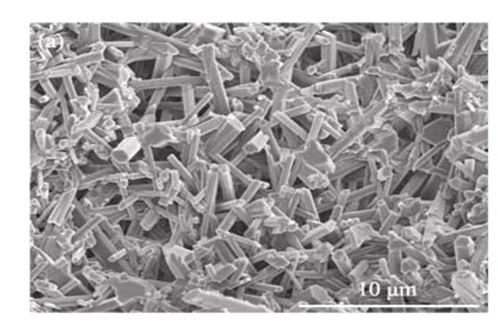

· 将纤维(或晶须)以一定的方式加入到陶瓷的基体中去,达到改善陶瓷材料脆性的目的 ;

· 用颗粒作为增韧剂,制备颗粒增韧陶瓷基复合材料;

· 提高纯度,通常99%纯度的材料和99.9%纯度的材料在性能上有非常大的差异;

· 添加微量元素,稳定陶瓷性能;

· 优化的烧结温度控制,全自动烧结系统。

耐腐蚀性

陶瓷材料有良好的耐蚀性,它们在腐蚀性介质中的腐蚀属于化学作用或伴随着物理机械作用而引起的破坏,其耐蚀能力与材料的化学成分、矿物学组成、孔隙、结构类型,高温下材料性质的变异以及腐蚀介质的性质等有关。

SSZ阀门选用的陶瓷材料具有优异的化学稳定性。高温下不氧化,对酸、碱、盐等均有较强的抗腐蚀能力,与许多熔融金属不发生作用,因此,陶瓷材料是极好的耐腐蚀材料,作为阀内件,可以抵御强酸强碱介质的腐蚀

抗弯强度

又叫弯曲强度,它反映的是矩形截面在弯曲应力作用下受拉面断裂时的最大应力。加载方式有三点弯曲和四点弯曲两种。

实际在阀内件使用中,若有高温或者不考虑因素之外,通常我们的阀内件都是陶瓷材料设计,然而阀球需要承受阀杆带动的传动力,所以球必须保证很好的抗弯强度,所以设计中,阀球通常我们会选择ZrO2,当然,除此以外我们还有别的材料可选。

抗压强度

也叫压缩强度,是指一定尺寸和形状的陶瓷试样在规定的试验机上受轴向应力作用破坏时,单位面积上新承受的载荷,是陶瓷材料在均匀压力下破碎时的应力。

抗热震性

是材料承受温度剧烈变化而不发生失效的能力。对于塑性较好的材料,可以通过塑性变形来松弛由于热震缩引起的热应力。

客户选择时,必须考虑我们提供的数据信息外,还需考虑瞬间温度的变化,比如时间在小于3s时,温度差有260℃,这个情况需要计算到选型中,超过陶瓷能承受的抗热冲击后,陶瓷材料可能会损坏,具体的选型事项,请联系SSZ授权点。

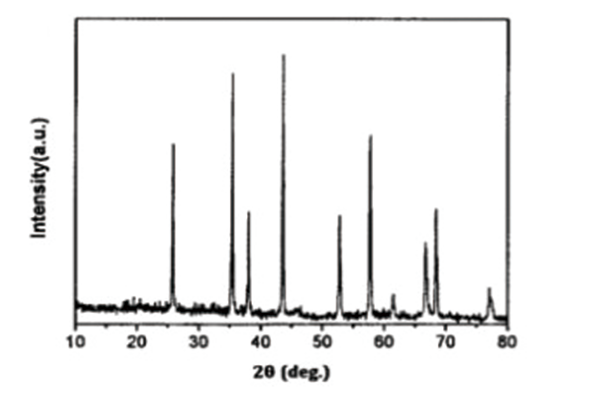

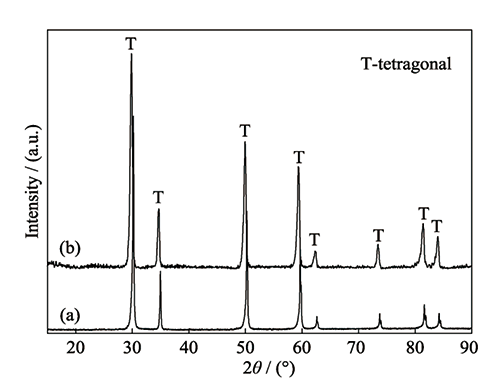

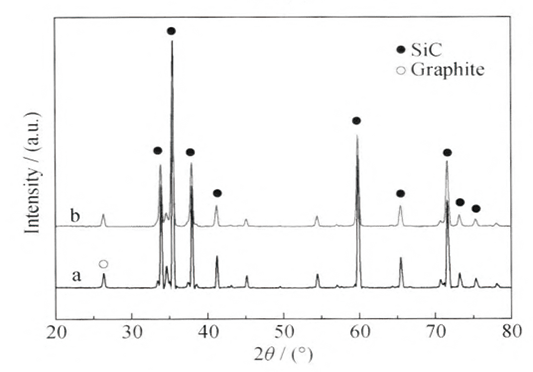

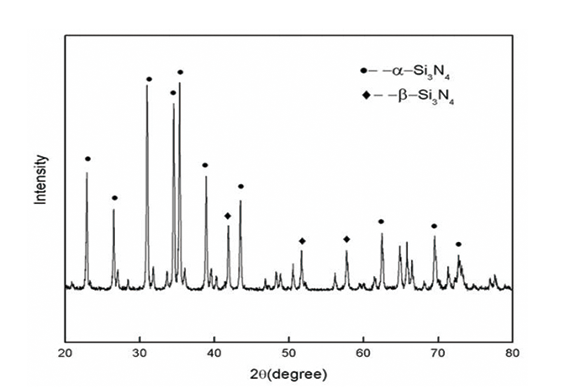

陶瓷XRD图谱

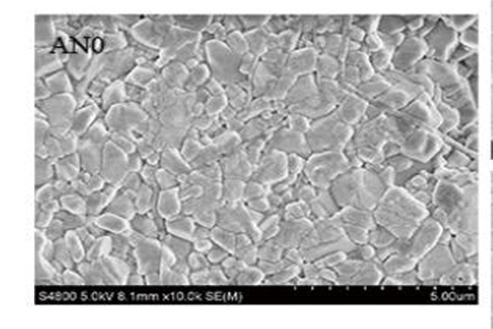

陶瓷SEM形貌图